ULTIMATE SOLUTION FOR CONVERTING INDUSTRIES

Application:-

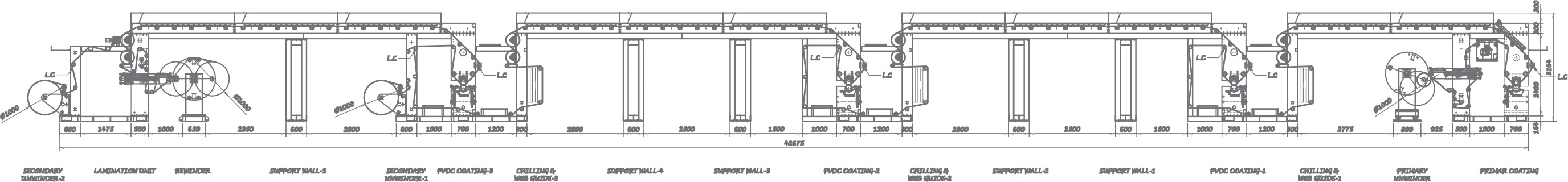

To coat Primer and Poly Vinyledene Chloride (PVDC) in a latex emulsion form in water on line through Air Knife, Chambered, Reverse Gravure Coating unit with a combination of drying system (horizontal web path) consist of I.R. dryer & hot air system distributed in multi zone.

Technical Specification:-

| Materials to be processed |

: Blister PVC 150μ - 500μ, Other Thin Film e.g. PET, BOPP for Food Packaging |

| Working Width | : 1000 - 1500 mm |

| Mechanical Speed | : 100 Mpm |

| Primer Coating GSM | : 1.0 – 2.0 |

| PVDC Coating GSM | : 2.0 – 10.0 |

General Specification:-

Chambered Doctor Blade in Reverse gravure coating application in a chilled water circulation bath.

Kiss coating with the help of a super finish coating roll and leveler and control of coating wt by the application of air knife during passing of the coated film through bridle roll.

Turret type unwind & rewind stand with safety chuck & air shaft. Top dryer hood will be provided with pneumatic cylinders for easy nozzle cleaning and easy material movement monitoring. The IR bank at the entry point of the dryer equipped with a pneumatic lifting system interlocked with machine start sequence. Air volumes can be controlled through suction damper, recirculation & exhaust dampers at each station all tray, tanks & dryer inside fabrication and machine portion coming in contact with PVDC vapor are made from SS – 316 material or epoxy coated.

All passing rollers of dryer will be driven by a synchronized separate drive. Interchangeable circulation system will ensure quick and easy change over from pass to pass. Material handling system through monorail at loading & unloading point. PVDC circulation system consists of S.S. tray with water circulation, specially designed anti foam circulation pump and jacketed tanks.

Get in touch

You will find yourself working in a true partnership that results in an incredible experience, and an end product that is the best.

Call us on

+91 9825064354

+91 7211145364

+91 7203095730

Email us

suddhaeng@yahoo.com

sales@suddhagroup.com